Time and date

CONSTRUCTION DIRECTORY

Closed Cell Spray Foam Solutions Contact Details

Address

38 St. Johns Court

Arthane

County Dublin

Dublin 5

Ireland

About Closed Cell Spray Foam Solutions

WDG System 14 is the most cost effective solution available when addressing the continuing deterioration of Asbestos roofs and wall cladding.

Conventional methods of abatement are either expensive or short term solutions but with WDG System 14 the building owner/occupier gets a high performing long lasting solution that is quicker, cheaper and less obtrusive to install than any other method. When all the benefits of the system are combined you will see just how cost effective WDG System 14 is, let us take you through the process.

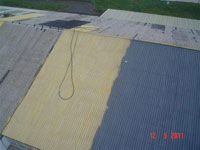

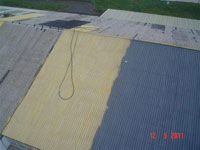

First we apply a minimum of 30mm high density roofing foam to a clean dry substrate, the application of this lightweight material repairs the roof eliminating all cracks, holes and loose sheets while adding structure to the substrate as the roofing foam has a tensile strength of 75psi.

The application of the roofing foam also eliminates thermal bridging, air-infiltration and noise infiltration while adding a level of insulation which reduces energy requirements saving on heating costs.

This roofing system is the only truly Monolithic roofing system in the world as the roofing foam application not only eliminates seams and joints, it also eliminates flashing’s, collars around protrusions, upstand and roof light details transitions between roofs and other buildings all in one application forming a complete one piece system no matter what shape or size the substrate may be while eliminating all the weakness’s of conventional roofing methods.

After the application of the roofing foam we apply a Silicone membrane, this is also spray applied in keeping with a seamless Monolithic system, this material is Hydrophobic (cannot be wetted) making the system impervious to the freeze thaw cycle and is 100% UV resistant. Combined the two components have been certified Class 1 in roof construction by FM Global approvals and carries an unlimited wind uplift guarantee, this is one of the many accreditation's that WDG System 14 has been awarded.

The installation of the system requires no downtime for a facility, complying with Health & Safety regulations the speed and unobtrusive nature of application are all benefits which reduce costs for the building owner/occupier.

All materials used to create this Monolithic roofing system are environmentally sustainable as is the finished roof, they are manufactured using low intensity production methods form rapidly renewable and recycled produce with no solvents, VOC’s or ODP turning an Asbestos or any other roofing substrate into a green roofing system while avoiding landfill costs.

The lifecycle of WDG System 14 makes for a long lasting sustainable roof with warranties to back this up, warranty options from 15 to 30 years are available and can be reinstated at the end of the warranty period by simply recoating the Silicone to the same specification, as the roofing foam will last indefinitely once it is protected from UV it is this that makes the system sustainable.

We can also apply Polyurethane foam to the underneath of the substrate encapsulating the entire roof and bringing the insulation value of the roof up to the standards of the building regulations.

Benefits

Conventional methods of abatement are either expensive or short term solutions but with WDG System 14 the building owner/occupier gets a high performing long lasting solution that is quicker, cheaper and less obtrusive to install than any other method. When all the benefits of the system are combined you will see just how cost effective WDG System 14 is, let us take you through the process.

First we apply a minimum of 30mm high density roofing foam to a clean dry substrate, the application of this lightweight material repairs the roof eliminating all cracks, holes and loose sheets while adding structure to the substrate as the roofing foam has a tensile strength of 75psi.

The application of the roofing foam also eliminates thermal bridging, air-infiltration and noise infiltration while adding a level of insulation which reduces energy requirements saving on heating costs.

This roofing system is the only truly Monolithic roofing system in the world as the roofing foam application not only eliminates seams and joints, it also eliminates flashing’s, collars around protrusions, upstand and roof light details transitions between roofs and other buildings all in one application forming a complete one piece system no matter what shape or size the substrate may be while eliminating all the weakness’s of conventional roofing methods.

After the application of the roofing foam we apply a Silicone membrane, this is also spray applied in keeping with a seamless Monolithic system, this material is Hydrophobic (cannot be wetted) making the system impervious to the freeze thaw cycle and is 100% UV resistant. Combined the two components have been certified Class 1 in roof construction by FM Global approvals and carries an unlimited wind uplift guarantee, this is one of the many accreditation's that WDG System 14 has been awarded.

The installation of the system requires no downtime for a facility, complying with Health & Safety regulations the speed and unobtrusive nature of application are all benefits which reduce costs for the building owner/occupier.

All materials used to create this Monolithic roofing system are environmentally sustainable as is the finished roof, they are manufactured using low intensity production methods form rapidly renewable and recycled produce with no solvents, VOC’s or ODP turning an Asbestos or any other roofing substrate into a green roofing system while avoiding landfill costs.

The lifecycle of WDG System 14 makes for a long lasting sustainable roof with warranties to back this up, warranty options from 15 to 30 years are available and can be reinstated at the end of the warranty period by simply recoating the Silicone to the same specification, as the roofing foam will last indefinitely once it is protected from UV it is this that makes the system sustainable.

We can also apply Polyurethane foam to the underneath of the substrate encapsulating the entire roof and bringing the insulation value of the roof up to the standards of the building regulations.

Benefits

- Cost's less to install than Asbestos removal

- No downtime for your facility

- Eliminates thermal bridging

- Eliminates air-infiltration

- No flashing's, seams or joints

- Wind resistant

- Quick, unobtrusive and safe to install

- Reduces noise infiltration

- Complies with Health & Safety regulations

- UL & FM Global approved

- Environmentally sustainable

- 15 to 30 year warranty options available

- 100% UV resistant

- Hydrophobic membrane (Not susceptible to freeze thaw cycles)

- Reduced energy cost's and carbon footprint